We provide solutions for pultrusion processes to …

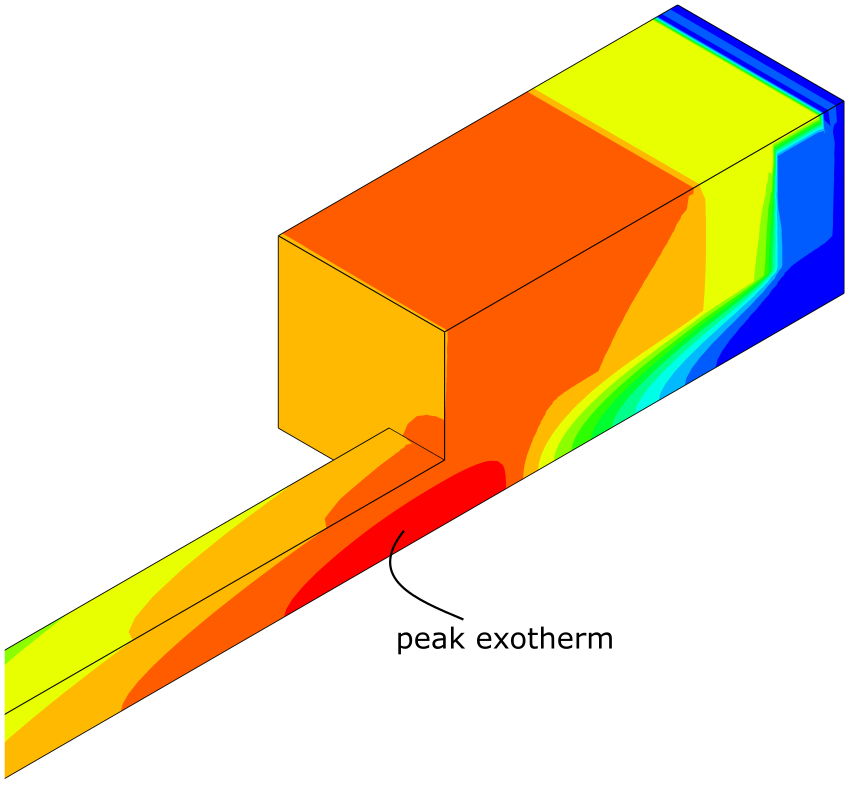

Control peak exotherm

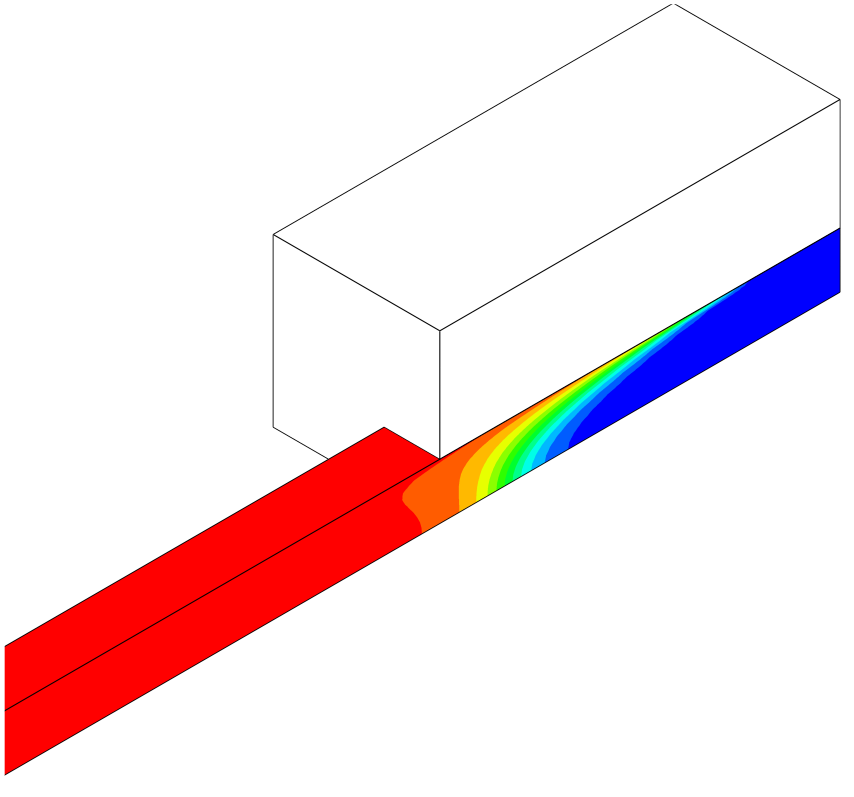

Maximize pulling speed

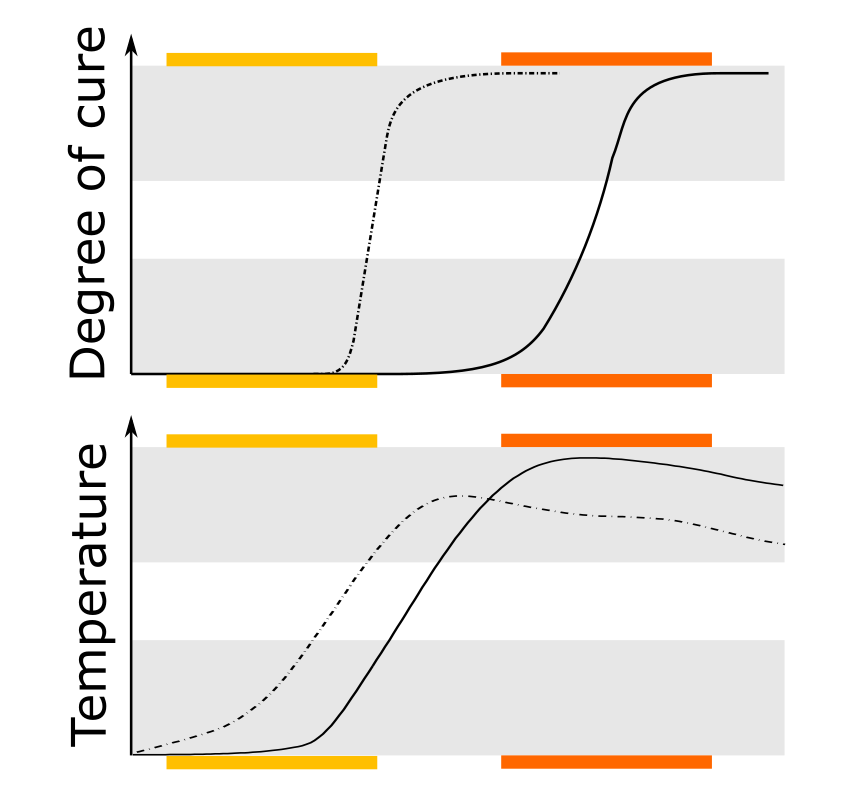

Optimize cure cycle

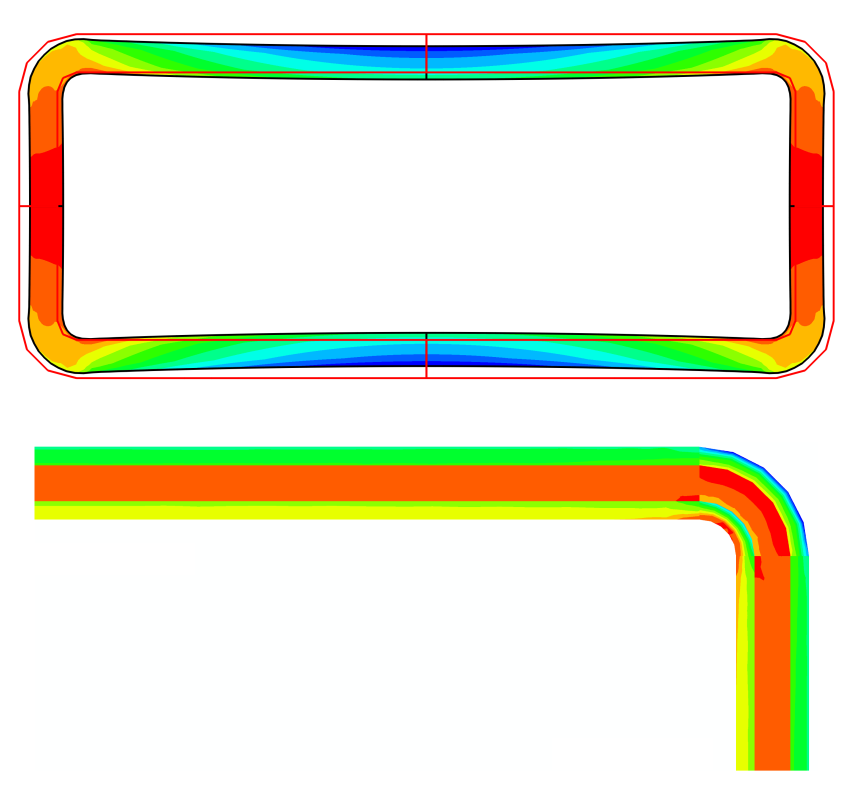

Minimize stress & distortion

Complex multiphysics phenomena

The pultrusion process is conceptually quite simple. However, the analysis of its physics, dynamics and definition of optimal processing parameters, are complex tasks.

There is a multiphysics phenomenon and a large number of variables involved in the pultrusion process. As a consequence, satisfactory experimental analysis for manufacturing purposes requires considerable time which is obviously not a cost-efficient approach.

Therefore, developing suitable computational models is crucial to analyse the process considering different composite manufacturing aspects. These are heat transfer, curing kinetics, polymerization phase transformations, resin flow and solid mechanics.

The expensive trial-and-error approaches for designing new products and optimising process conditions can be avoided using PultruSim software.